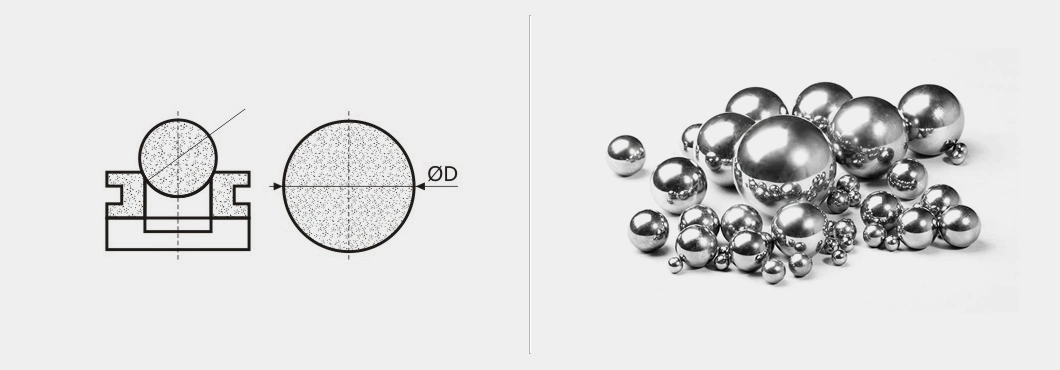

Tungsten carbide ball for Bearing

Carbide Balls:

Carbide balls, commonly known as tungsten steel balls, refer to balls and balls made of cemented carbide. The carbide balls are ideal for use in harsh environments, extremely resistant to abrasion, impact, corrosion and hard. Deformation.

Raw Material:

The cemented carbide ball is based on a high hardness refractory metal carbide (WC, TiC) micron powder, with cobalt (Co) or nickel (Ni), molybdenum (Mo) as a binder, in a vacuum furnace or Powder metallurgy products sintered in a hydrogen reduction furnace are currently available in the YG, YN, YT, and YW series.

Classification:

Carbide balls mainly include blank balls, fine grinding balls, punching balls, bearing balls, ball balls, non-magnetic balls, Monel balls, through-hole balls, measuring balls, scratching balls, and ball beads.

Features:

The hard alloy ball has high hardness, wear resistance, corrosion resistance, bending resistance and harsh use environment, and can replace all steel ball products. The hardness of the cemented carbide ball is ≥90.5, and the density is 14.9 g/cm3.

Application:

Carbide balls are used in a wide range of applications, such as: precision parts punching, precision bearings, instruments, meters, pens, sprayers, pumps, mechanical parts, sealing valves, brake pumps, punching holes, oil fields, Hydrochloric acid laboratory, hardness measuring instrument, fishing gear, counterweight, decoration, finishing and other high-end industries!

Common Grades :

| Grade | Component | hardness | density | MPa | metallographic analysis | |

| WC | CO | HRA | g/cm³ | g/m³ | ||

| YG6 | 94% | 6% | 91 | 14.6-15.0 | 1700 | A02B02C02 |

| YG8 | 92% | 8% | 89 | 14.4-14.8 | 1800 | A02B02C02 |

Precision parameters of cemented carbide ball:

| PRECISION CLASS | VARIATION | SPHERICAL | SURFACE | TOLERANCE | LOT VARIATION |

| G3 | 0.0762μm | 0.0762μm | 0.0127μm | ±0.762μm | 0.127μm |

| (0.000003″) | (0.000003″) | (0.0000005″) | (±0.0003″) | (0.000003″) | |

| G5 | 0.127μm | 0.127μm | 0.02μm | ±1.27μm | 0.254μm |

| (0.000005″) | (0.000005″) | (0.0000008″) | (±0.0005″) | (0.00001″) | |

| G10 | 0.254μm | 0.254μm | 0.0254μm | ±2.54μm | 0.508μm |

| (0.00001″) | (0.00001″) | (0.000001″) | (±0.0001″) | (0.00002″) | |

| G15 | 0.381μm | 0.381μm | 0.0254μm | ±2.54μm | 0.0762μm |

| (0.000015″) | (0.000015″) | (0.000001″) | (±0.0001″) | (0.00003″) | |

| G16 | 0.4064μm | 0.4064μm | 0.0254μm | ±2.54μm | 0.8128μm |

| (0.000016″) | (0.000016″) | (0.000001″) | (±0.0001″) | (0.000032″) | |

| G24 | 0.6096μm | 0.6096μm | 0.0508μm | ±2.54μm | 1.2192μm |

| (0.000024″) | (0.000024″) | (0.000002″) | (±0.00001″) | (0.000048″) | |

| G25 | 0.635μm | 0.635μm | 0.0762μm | ±2.54μm | 1.27μm |

| (0.000025″) | (0.000025″) | (0.000003″) | (±0.0001″) | (0.00005″) | |

| G48 | 1.2192μm | 1.2192μm | 0.0762μm | ±0.508μm | 2.4384μm |

| (0.000048″) | (0.000048″) | (0.000003″) | (±0.0002″) | (0.000096″) | |

| G50 | 1.27μm | 1.27μm | 0.0762μm | ±7.62μm | 2.54μm |

| (0.00005″) | (0.00005″) | (0.000003″) | (±0.0003″) | (0.0001″) |

Reference table of common specifications:

| diameter (mm) | density (g/cm³) | piece weight (g/pcs) |

| 2 | 18 | 0.075 |

| 2.5 | 18 | 0.147 |

| 3 | 18 | 0.254 |

| 3.5 | 18 | 0.404 |

| 4 | 18 | 0.603 |

| 4.5 | 18 | 0.859 |

| 5 | 18 | 1.178 |

| 5.5 | 18 | 1.567 |

| 6 | 18 | 2.035 |

| 6.5 | 18 | 2.587 |

| 7 | 18 | 3.231 |

| 7.5 | 18 | 3.975 |

| 8 | 18 | 4.824 |

| 8.5 | 18 | 5.786 |

| 9 | 18 | 6.868 |

| 9.5 | 18 | 8.078 |

| 10 | 18 | 9.421 |

| 12 | 18 | 16.280 |