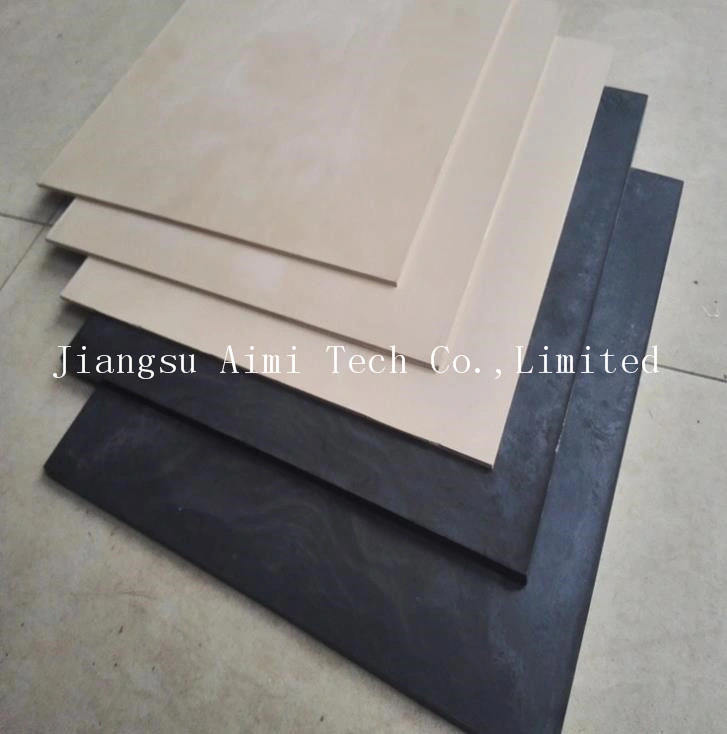

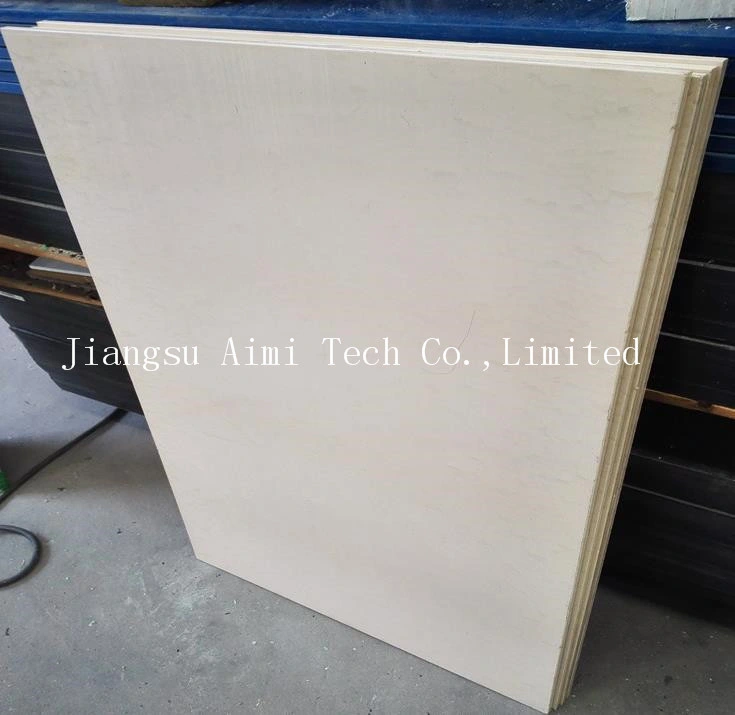

Product introduce

PPS (polyphenylene sulfide) products offer the broadest resistance to chemicals of any high performance plastic. They have no known solvents below 392°F and are inert to steam, strong bases, fuels and acids. Minimal moisture absorption and a very low coefficient of linear thermal expansion along with stress-relieving processes make these PPS products ideally suited for precise-tolerance machined components. In addition, PPS products exhibit excellent electrical characteristics and are inherently flame retardant. PPS is ideally suited for plastic components in automotive, electrical, appliance and industrial applications.

Polyphenylene sulfide (PPS) is an organic polymer consisting of aromatic rings linked with sulfides. Synthetic fiber and textiles derived from this polymer are known to resist chemical and thermal attack. PPS is used to make filter fabric for coal boilers, papermaking felts, electrical insulation, specialty membranes, gaskets, and packings. PPS is the precursor to a conducting polymer of the semi-flexible rod polymer family. The PPS, which is otherwise insulating, can be converted to the semiconducting form by oxidation or use of dopants

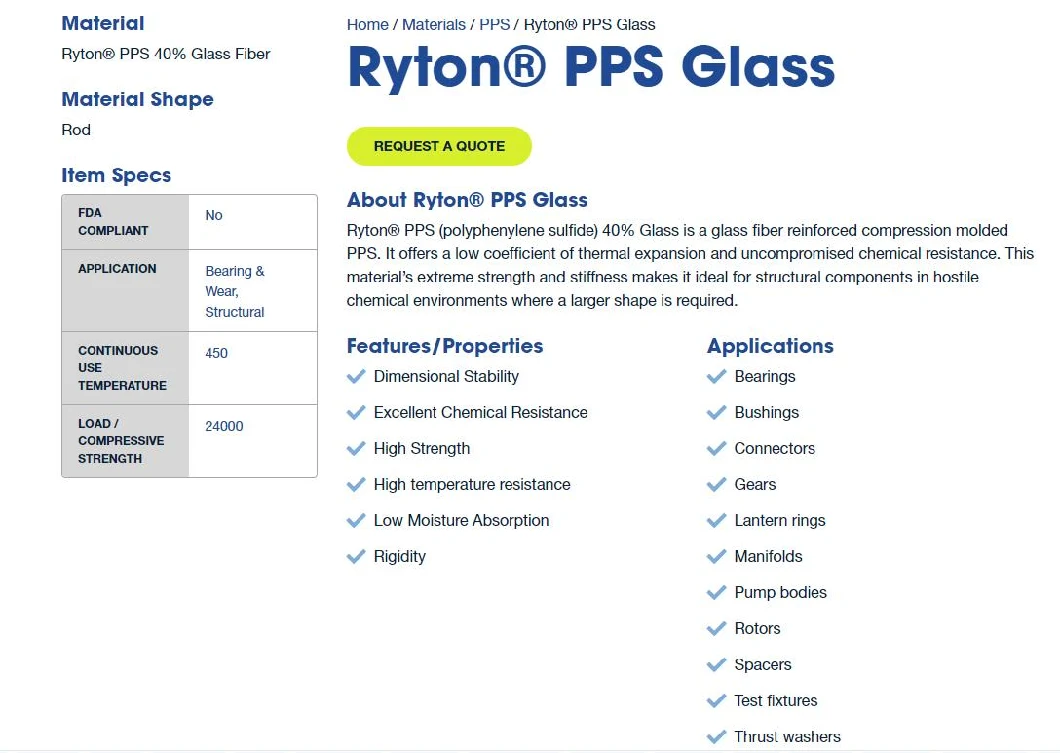

| OVERVIEW of PPS - 40% Glass-Filled (Generic) |

| PPS - Polyphenylene Sulfide (Generic) is available in Virgin (unfilled) or 40% Glass-Filled Grades Linear polyphenylene sulphide is a partially crystalline material that provides very high mechanical performance combined with excellent resistance to heat and chemicals (continuous service temperature resistance up to approximately + 464 °F), high dimensional stability and creep strength. Its LOI is one of the highest among polymers. Excellent hardness and rigidity are other characteristics of PPS. By virtue of its strength and affordability, it bridges the gap between the partially crystalline industrial plastics and PEEK. Thanks to reinforcement with 40% glass fibres, strengths are attained that are comparable with light metals. Typical Applications: Components in equipment construction, pump parts, fan elements, impellers, valve balls/seats/ seals, plastic parts and motor vehicle parts. · We offer PPS and PPS-40GF rods from in 3/4" to 2" diameters. · Also see Ryton® R4 (40% Glass-Filled PPS from Solvay) · Ryton PPS 40% Glass |

| FEATURES AND BENEFITS of PPS - 40% Glass-Filled (Generic) |

| Features of 10% Glass-Filled PPS (Polyphenylene Sulfide): · Very high strength and hardness · High rigidity · High heat deformation resistance · High dimensional resistance · Very high chemical resistance · Very good electrical insulation properties · High resistance to the effects of weather · High hydrolysis resistance in the case of non-reinforced types |

Technical Date Sheet | |||

Properties | Test Method | Units | Value |

Physical Property | |||

Specific gravity | ASTM D792 | g/cm3 | 1.99 |

Water absorption(23ºC,24hr) | ASTM D570 | % | 0.03 |

Molding shrinkage | ASTM D570 | % | 0.2~0.6 |

Mechanical properties | |||

Tensile strength at break | ISO527-2 | MPa | 135 |

Elongation at break | ISO527-2 | % | 0.8 |

Flexural strength | ISO178 | MPa | 210 |

Flexural modulus | ISO178 | MPa | 19000 |

Izod impact,Notched(ISO) | ISO180 | KJ/m2 | 6 |

Izod impact,Unotched(ISO) | ISO180 | KJ/m2 | 15 |

Thermal properties | |||

Deflection Temperature at 1.8 MPa | ASTM D648 | ºC | 260 |

Flammability | |||

Flammability | UL94 |

| V-0 |

Electrical properties | |||

Volume resistivity | ASTM D257 | Ω·CM | 1.0E+15 |

Dielectric strength | ASTM D149 | KV/m | 16 |

Arc resistance | ASTM D495 | Sec | 185 |

Features | Glass /mineral filled ,injection grade | ||

Application:Automotive interior parts, electronic applications,precision parts and devices.

FAQ

Q1. What is your terms of payment?

A: T/T, details could be discussed.

A: FOB, CFR, CIF, DDU, EXW, etc.

Q2. How about your delivery time?

A: Generally, 7 to 12 days upon advance payment.

The specific delivery time depends on your detailed requirements and the quantity of your order.

Q3. Can you produce according to the samples?

A: Yes, we can offer samples or technical drawings.

Q4. What is your sample policy?

A: We could offer the sample for free charge but your esteemed company will pay the cost of freight.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% inner inspection in our own laboratory and plant before delivery.

Q6: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them.

Our Advantages:

1.We are very experienced with this field(more than 10 years);

2.Good after-sales service

3.100% quality guaranteed;

4.We accept sample order for testing;

5.Strong supply ability

6.Made in China gold members with high credit guarantee.

We develop and manufacture high performance engineering thermoplastics compounds custom made to suit your demanding industrial environments requirements.